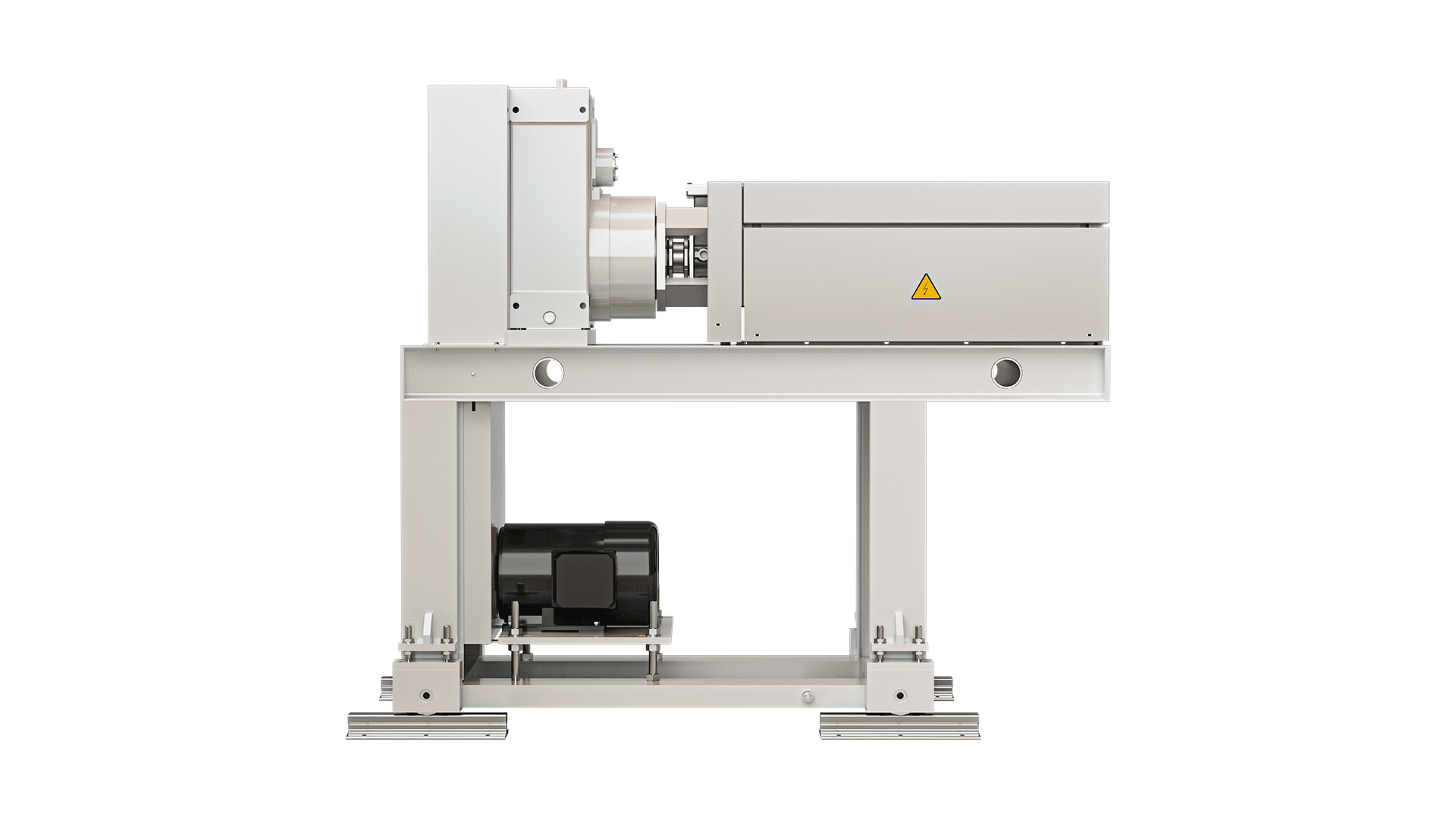

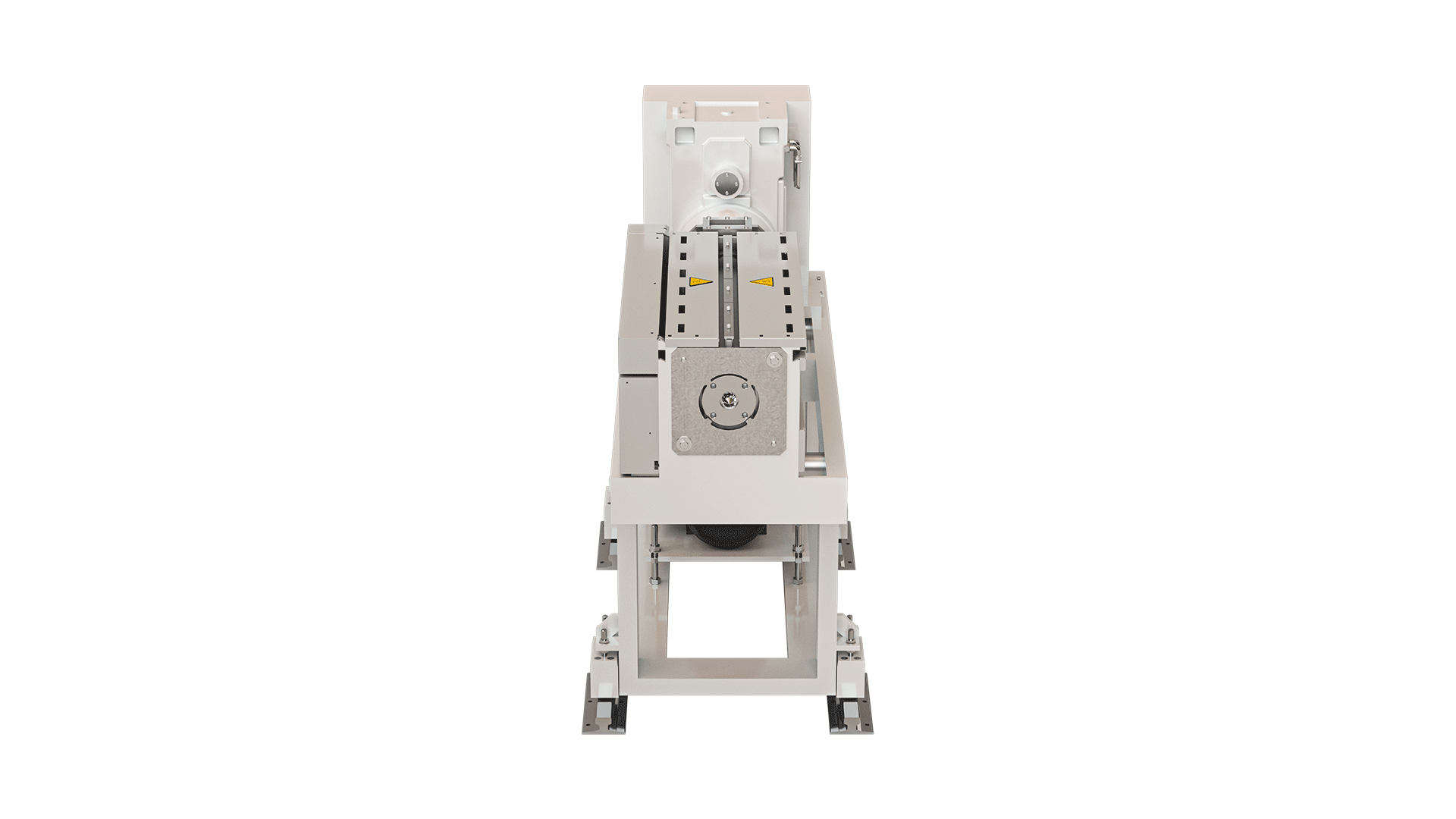

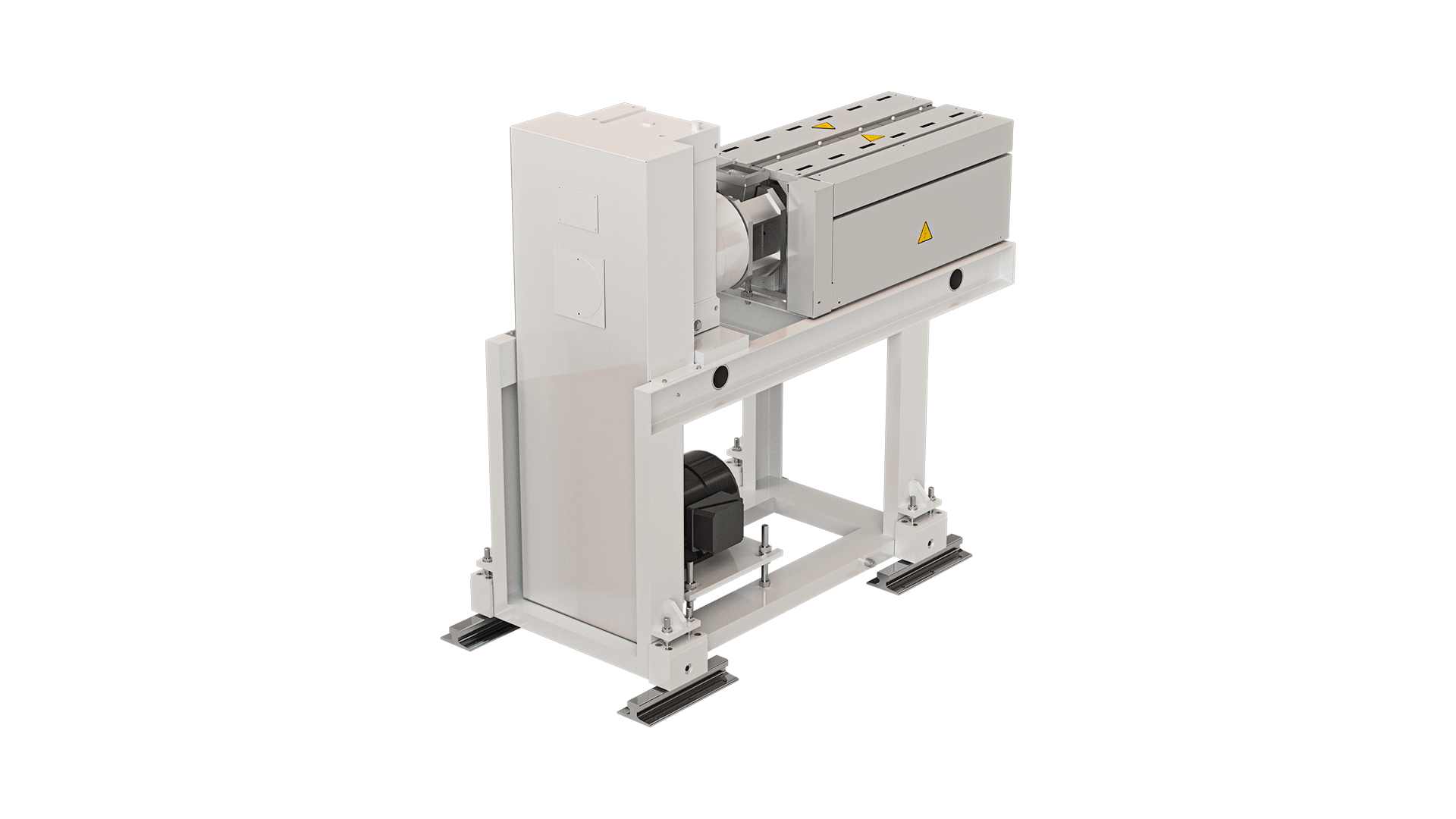

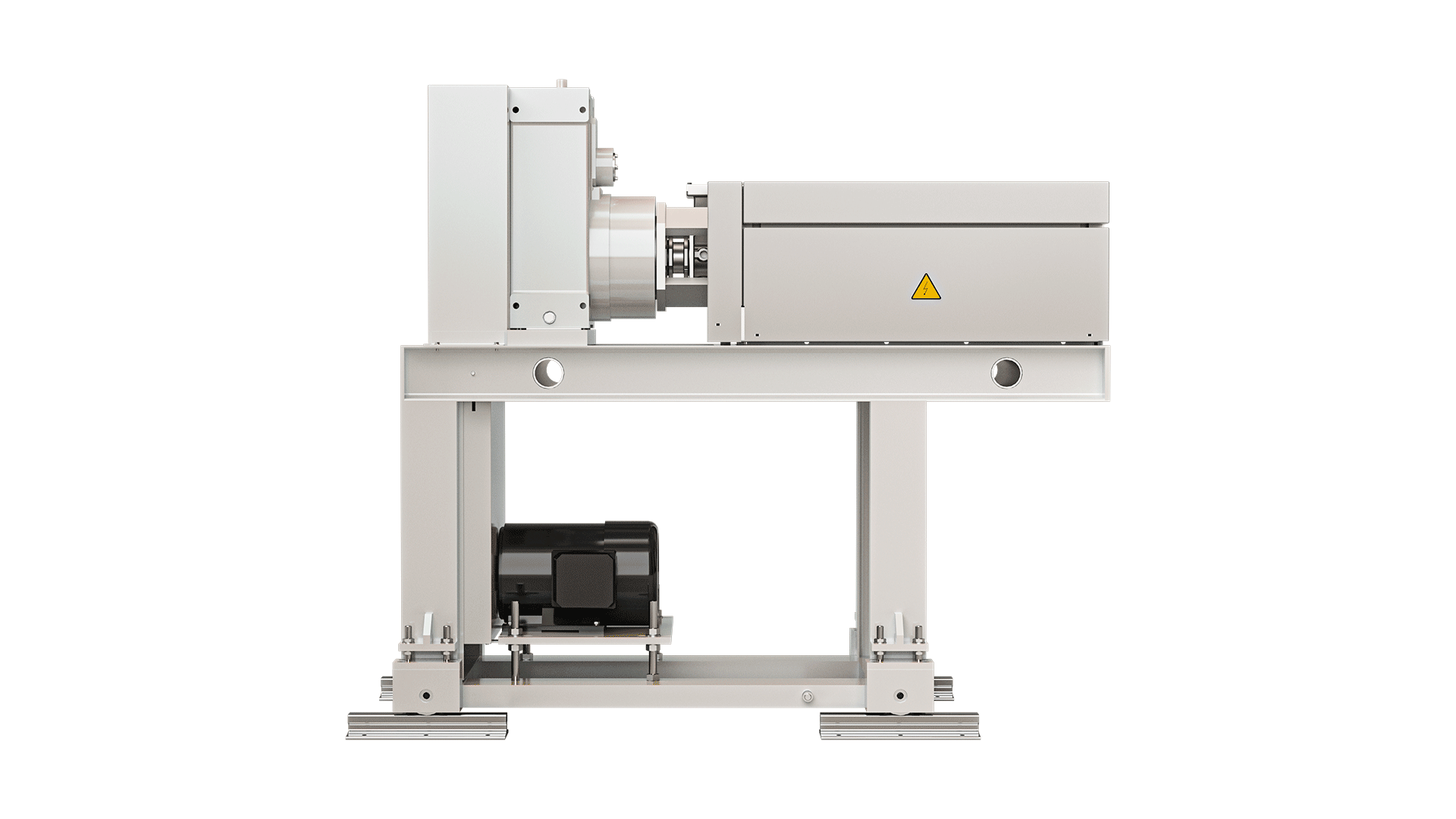

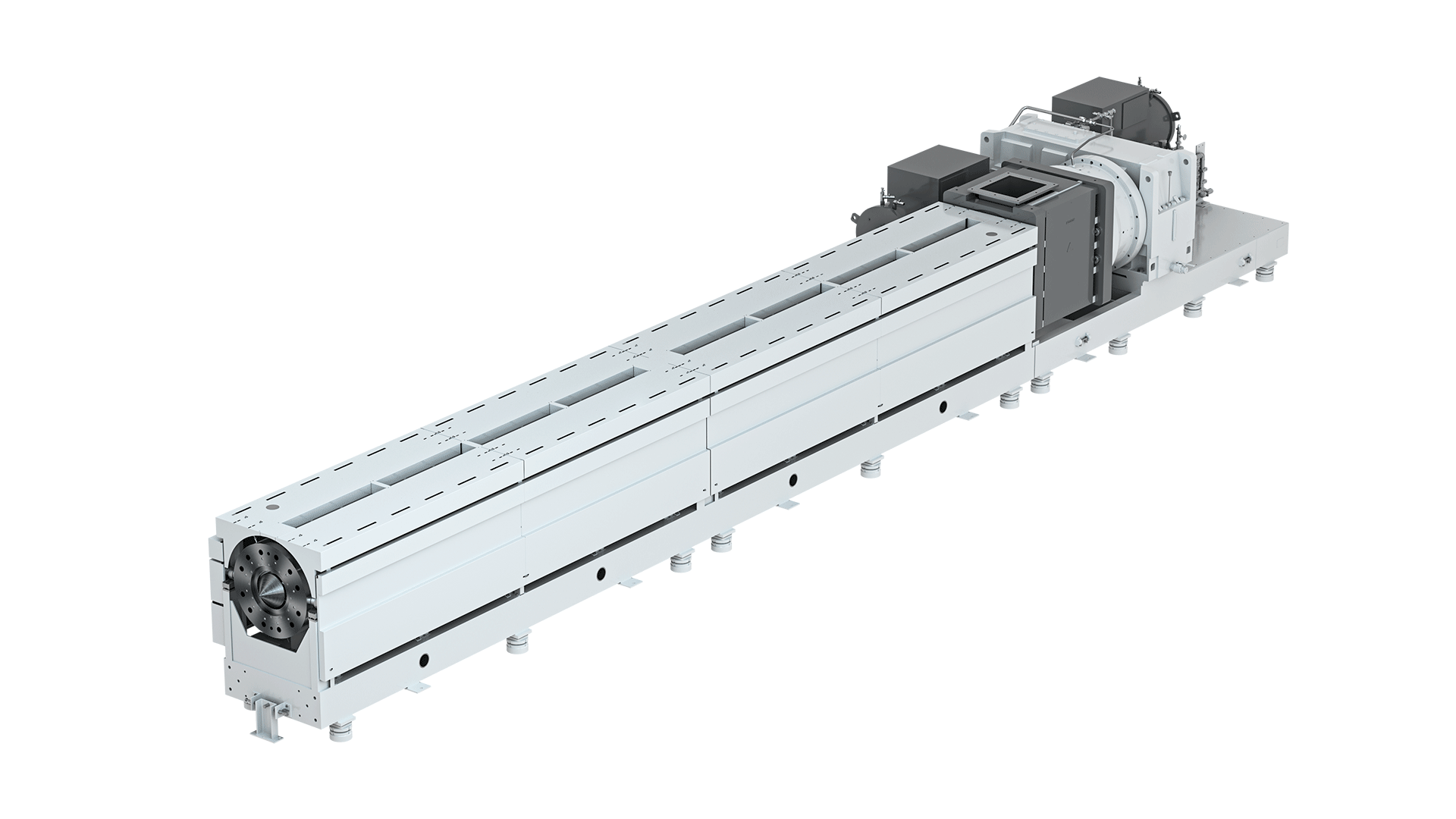

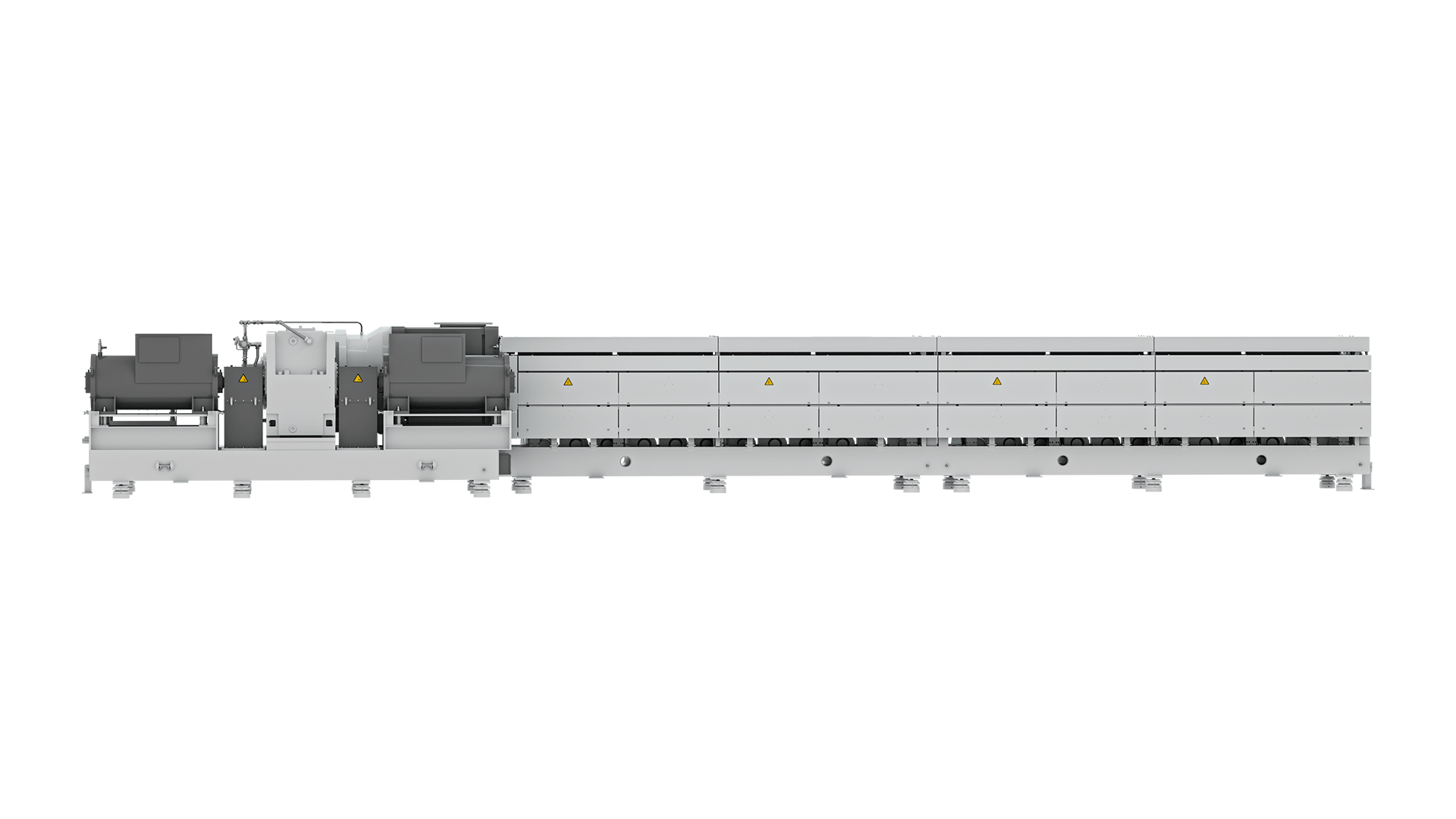

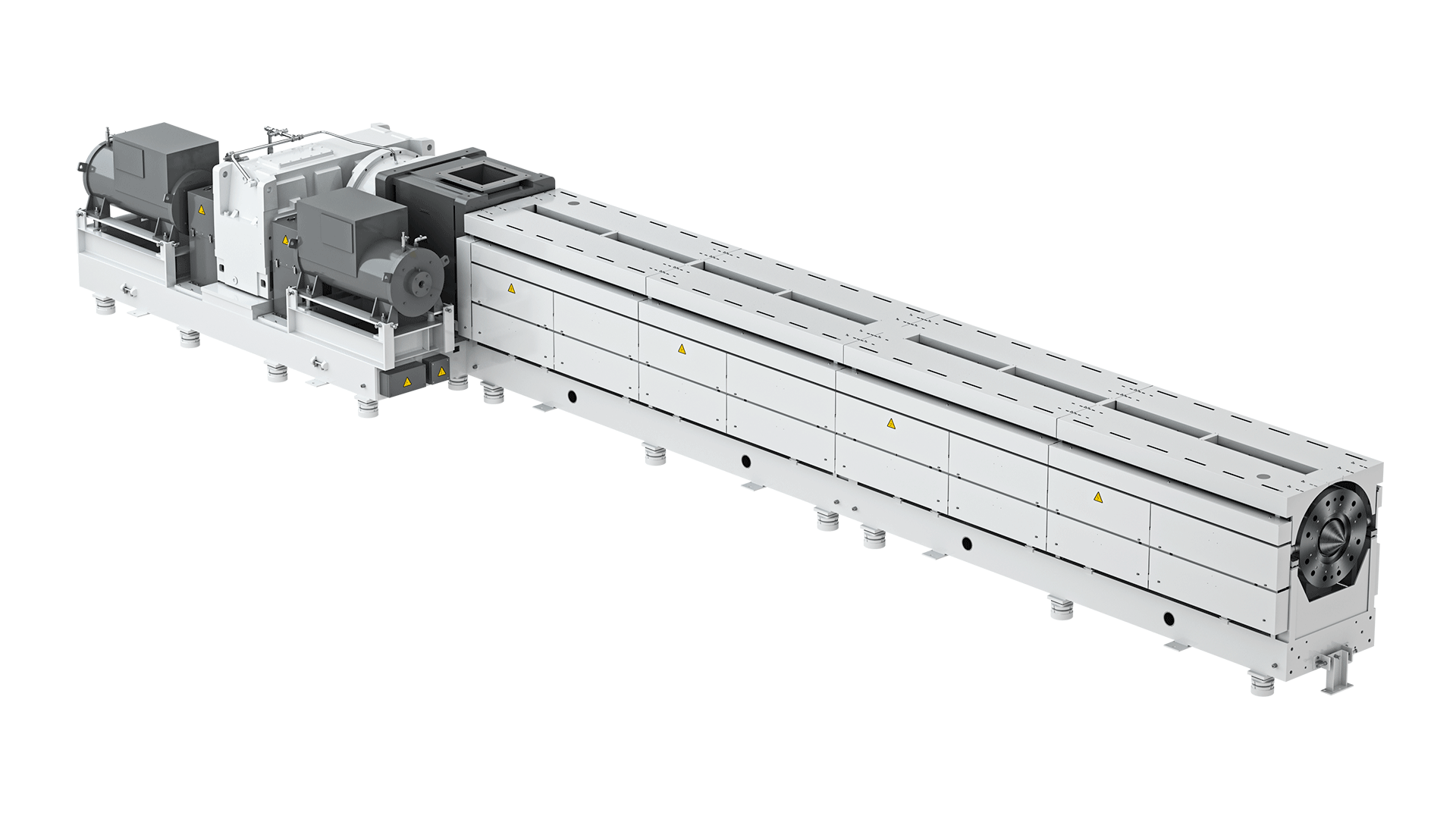

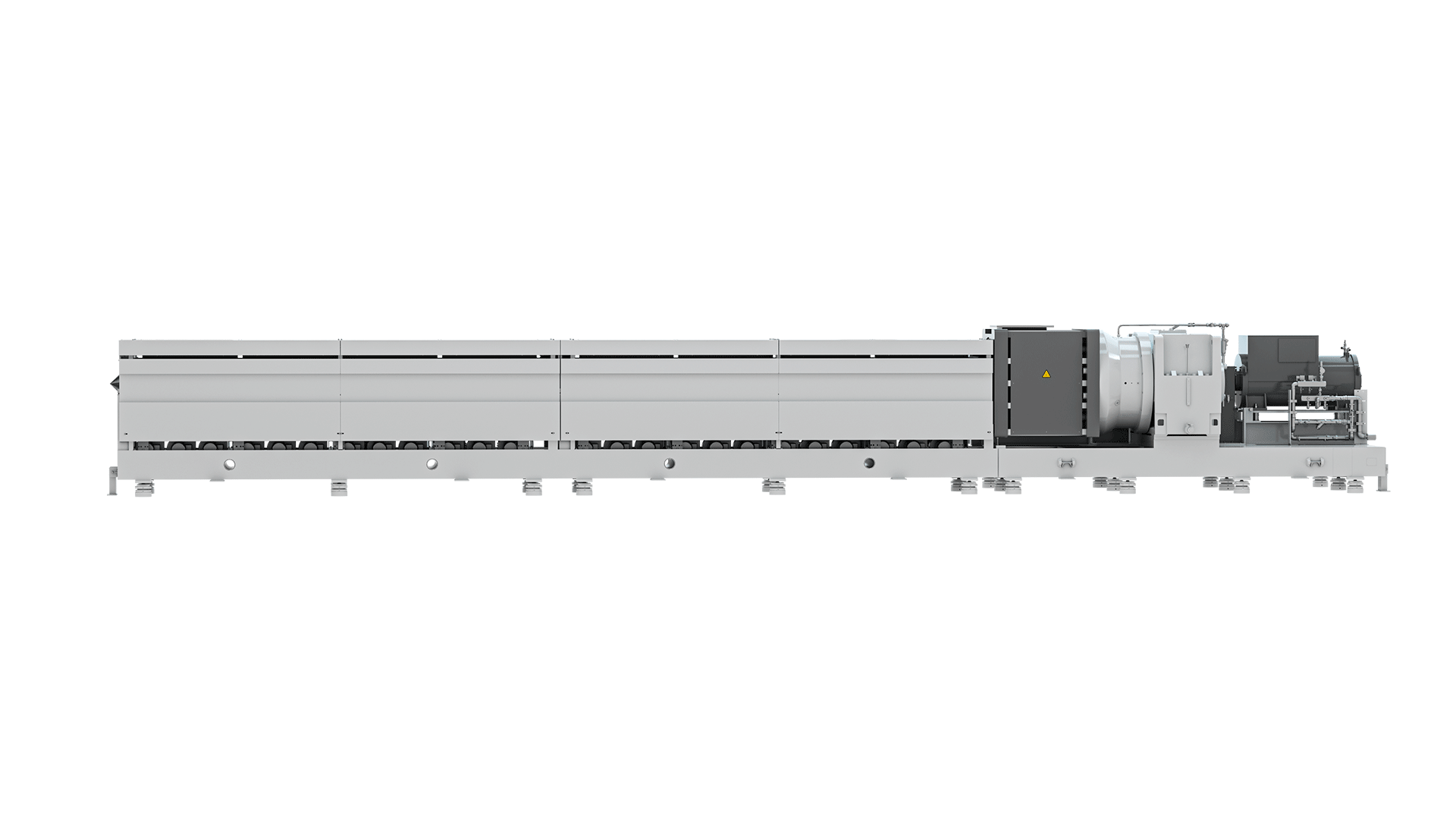

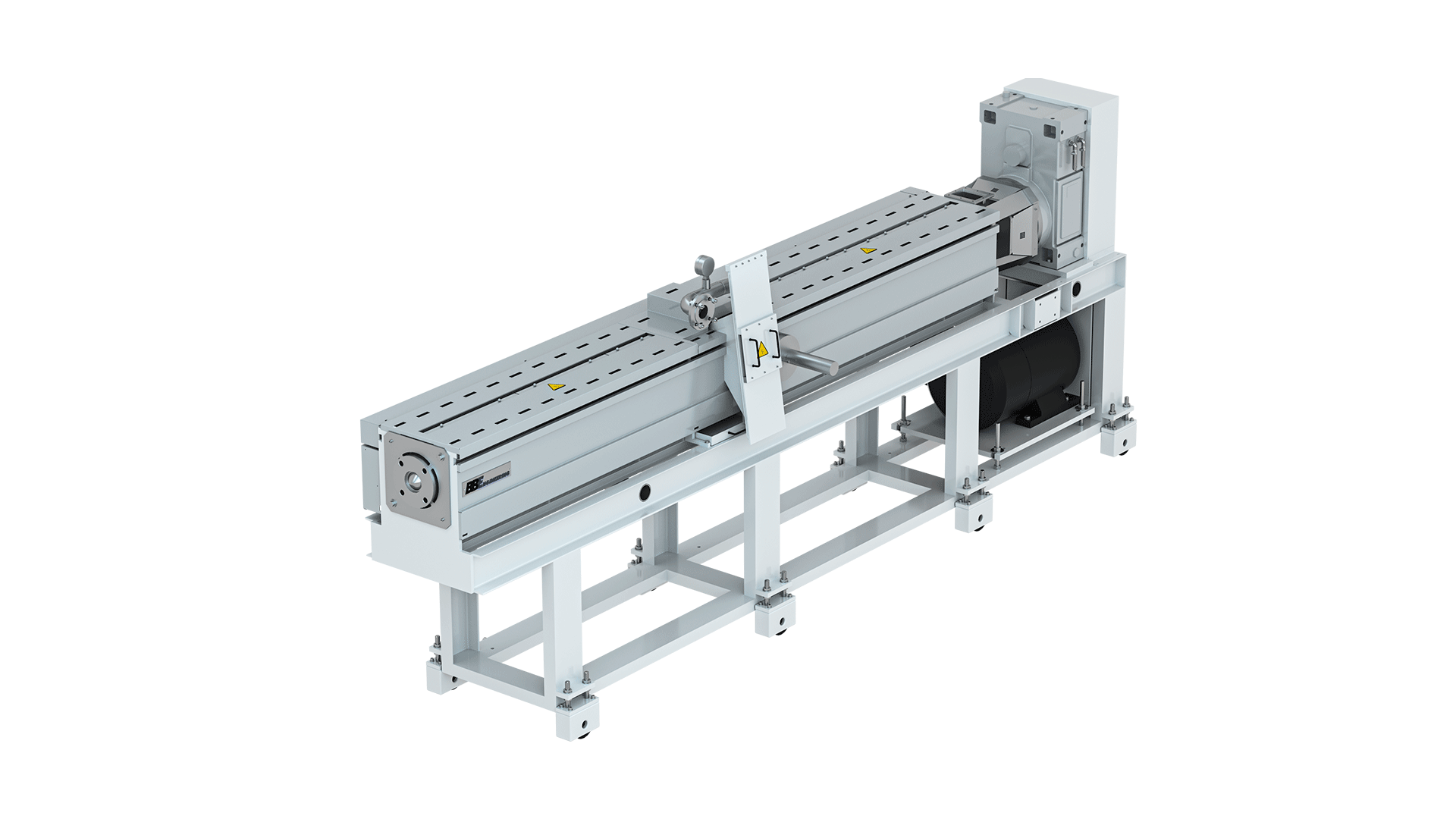

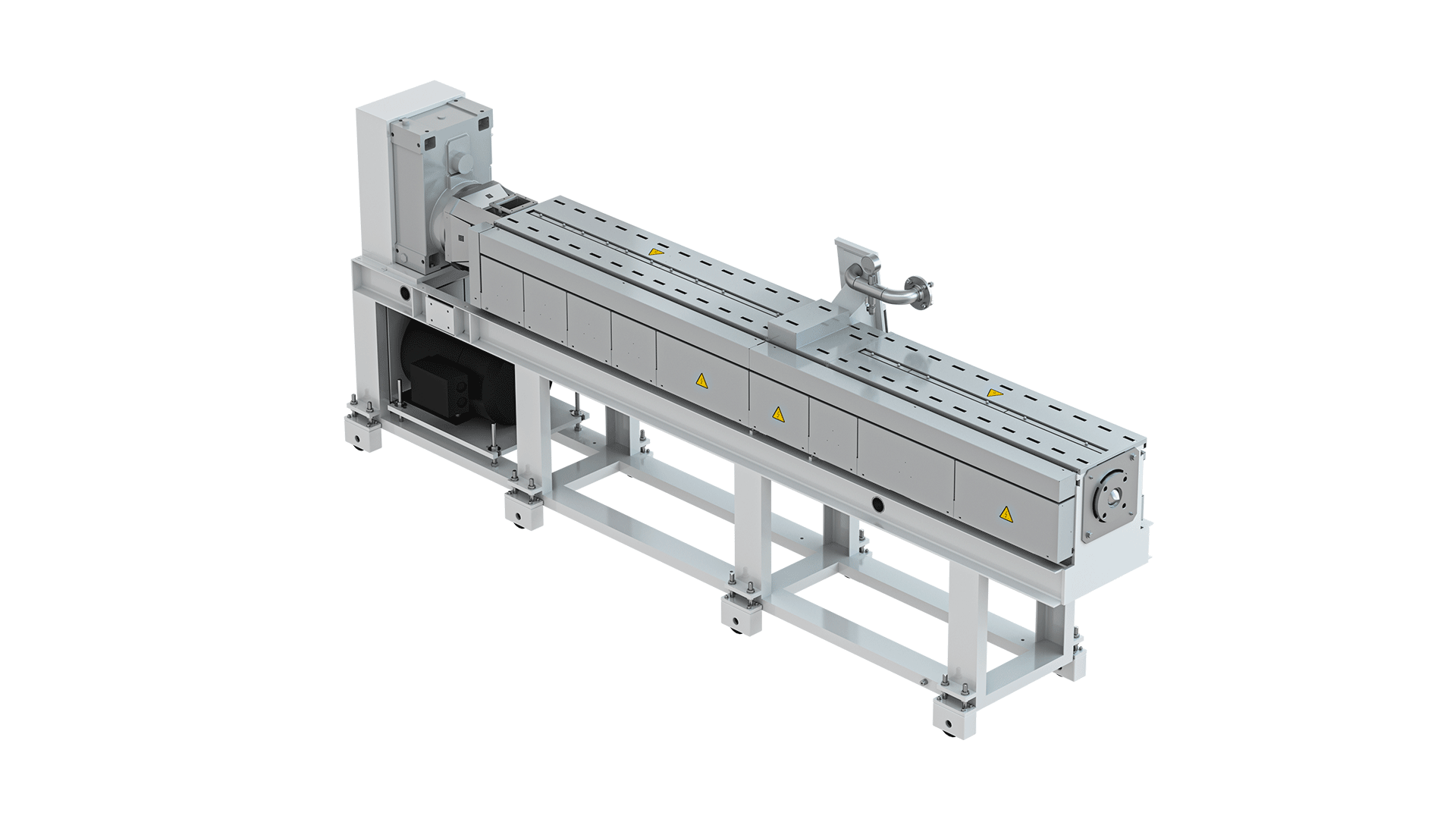

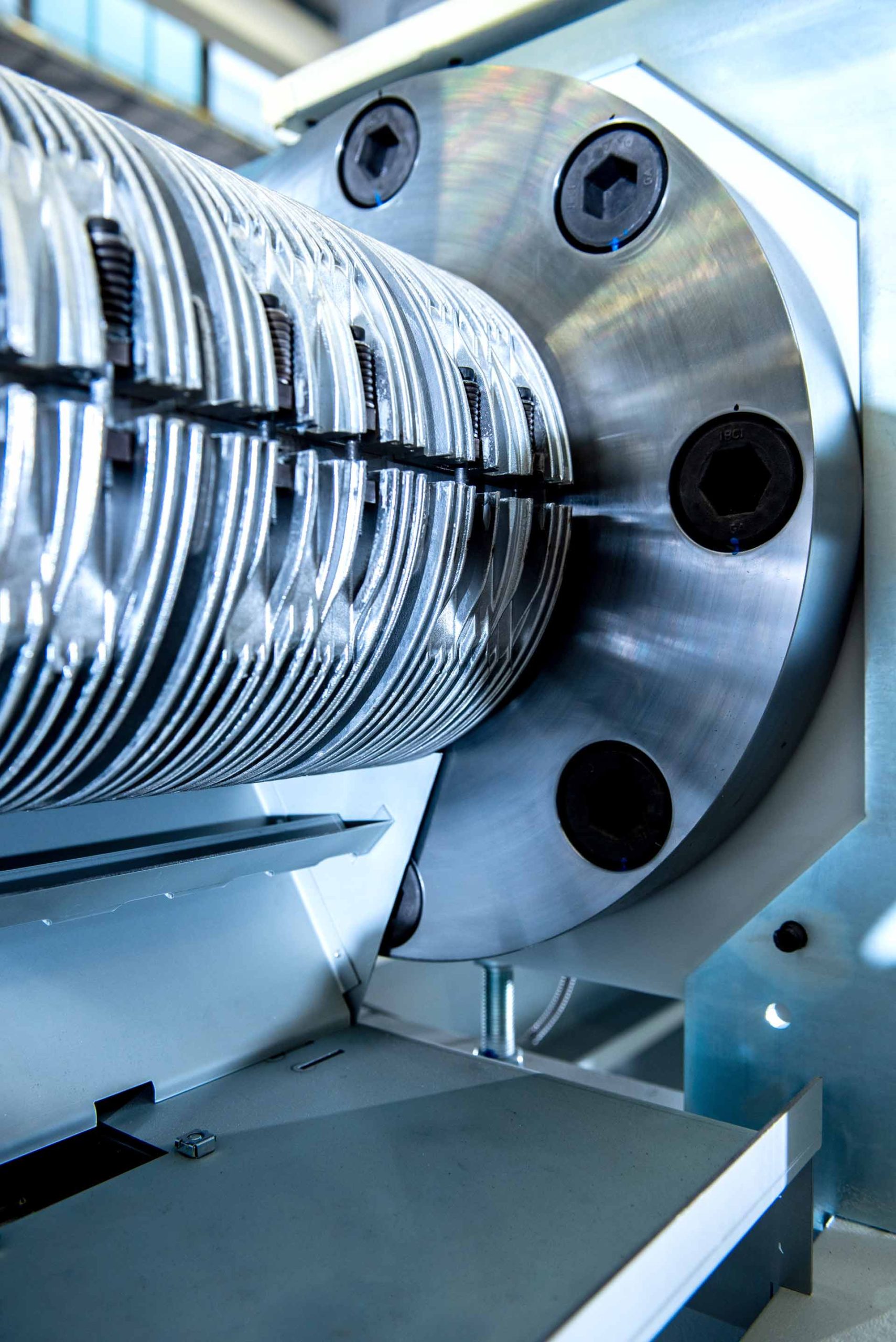

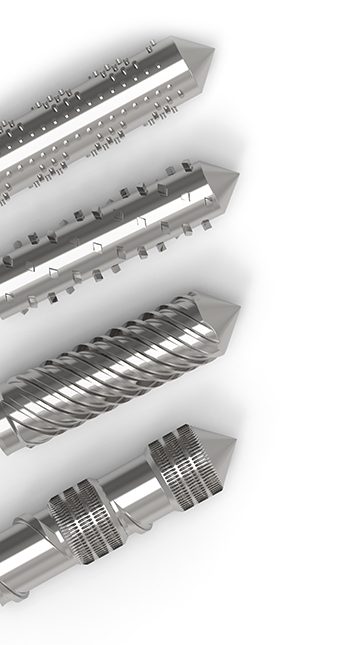

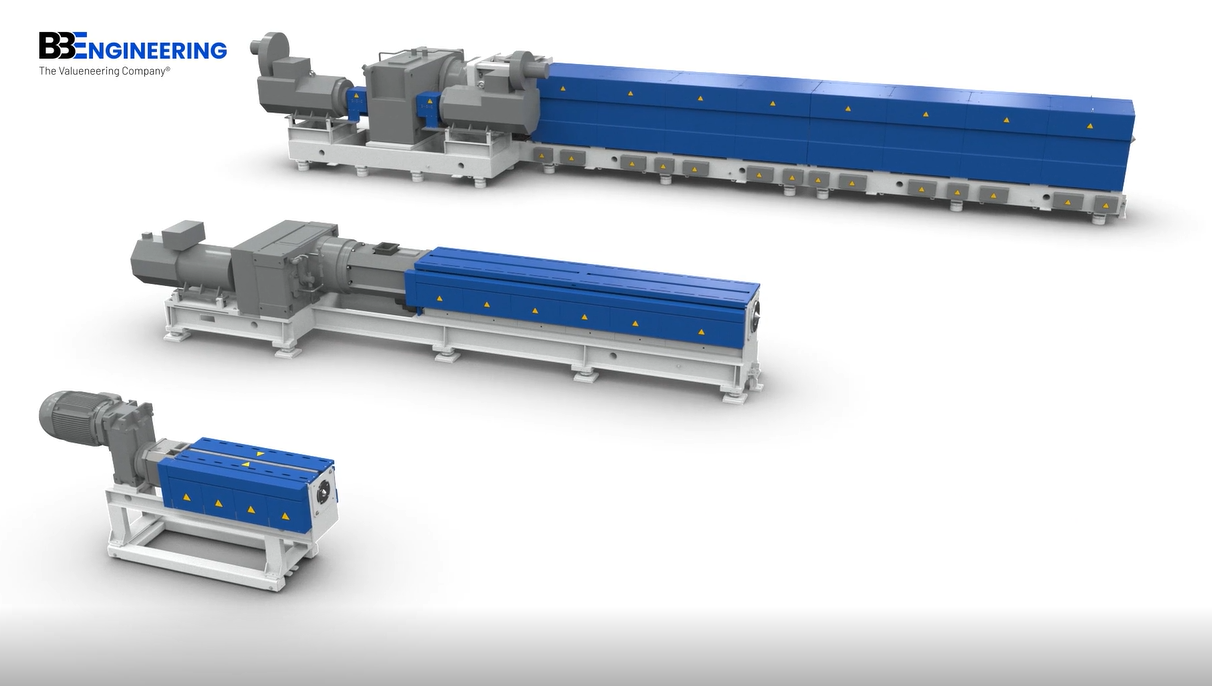

Decades of experience for absolutely homogeneous melts

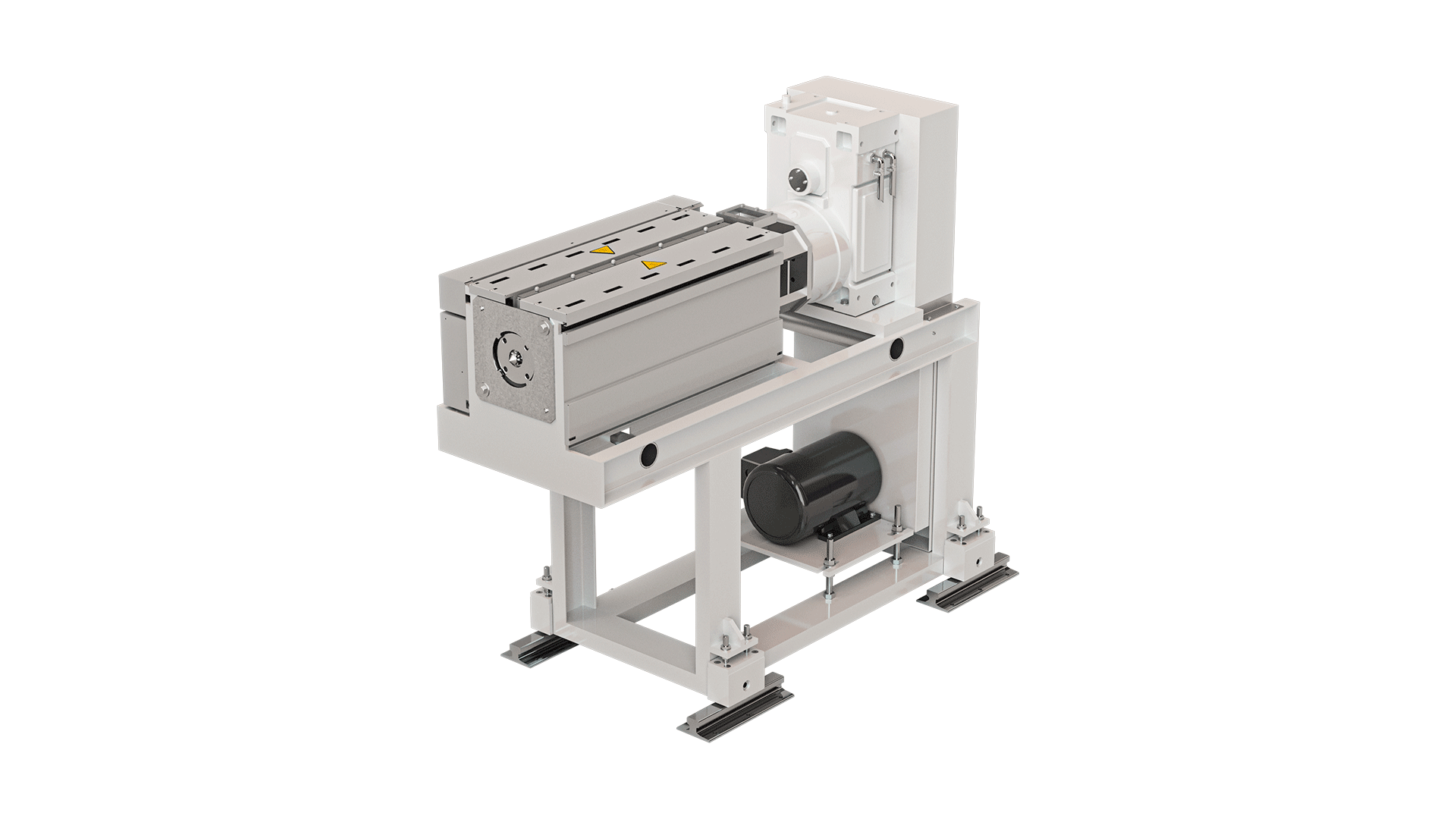

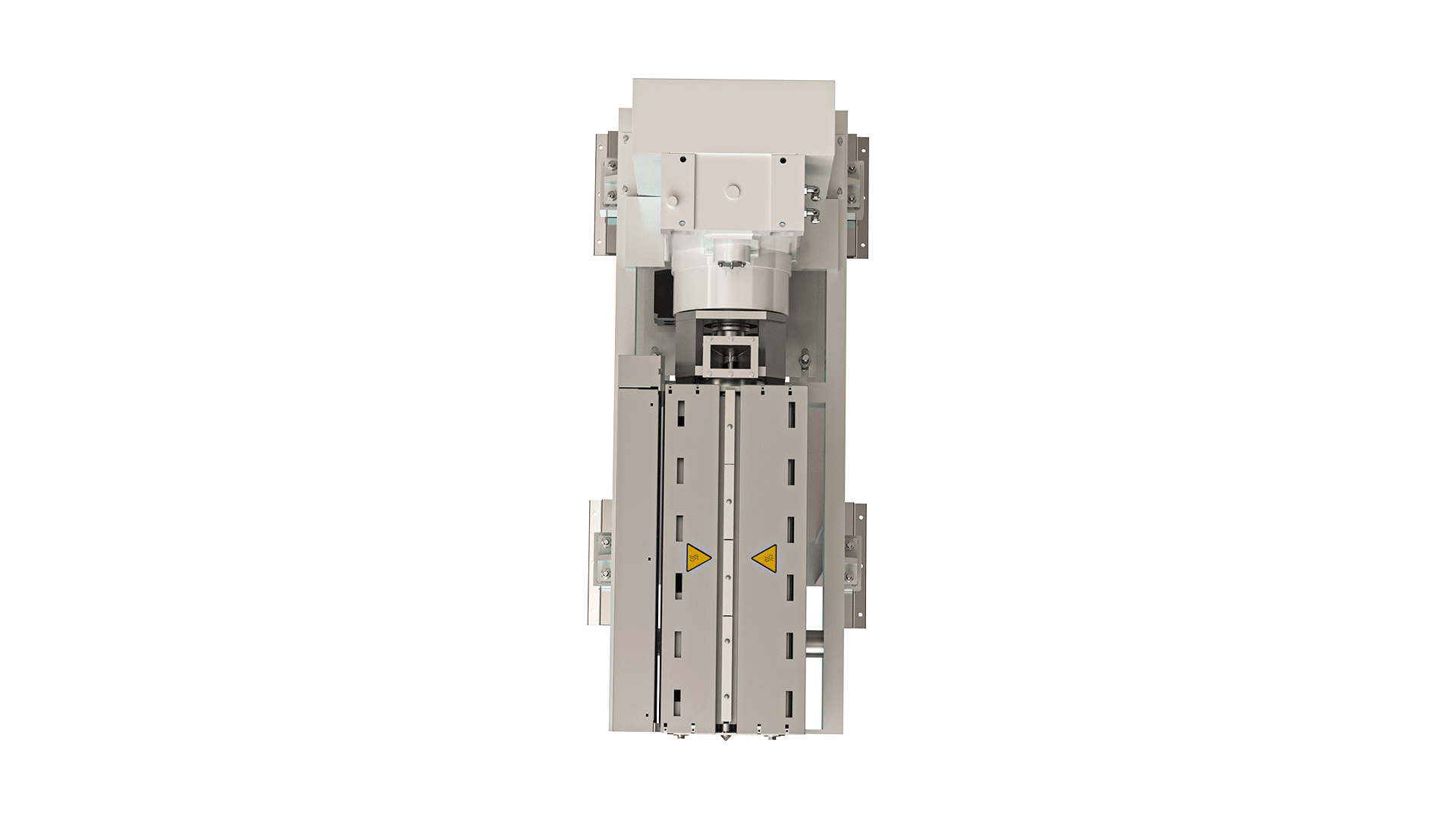

We offer a wide range of single-screw extruders: from small to large and for different polymers and applications. We always rely on high-quality technology - for your qualitative products. This is how our extruders have proven themselves for decades.