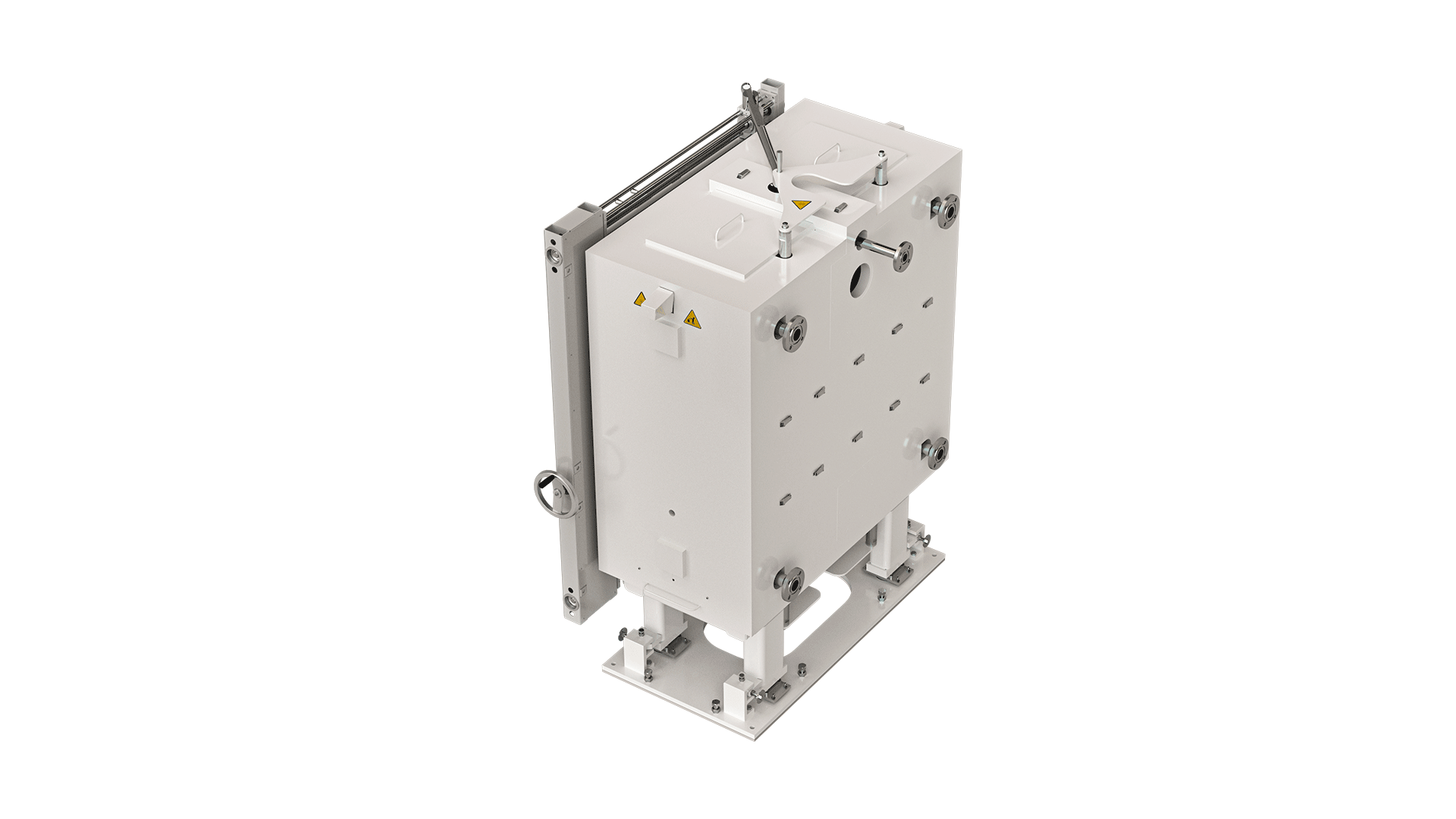

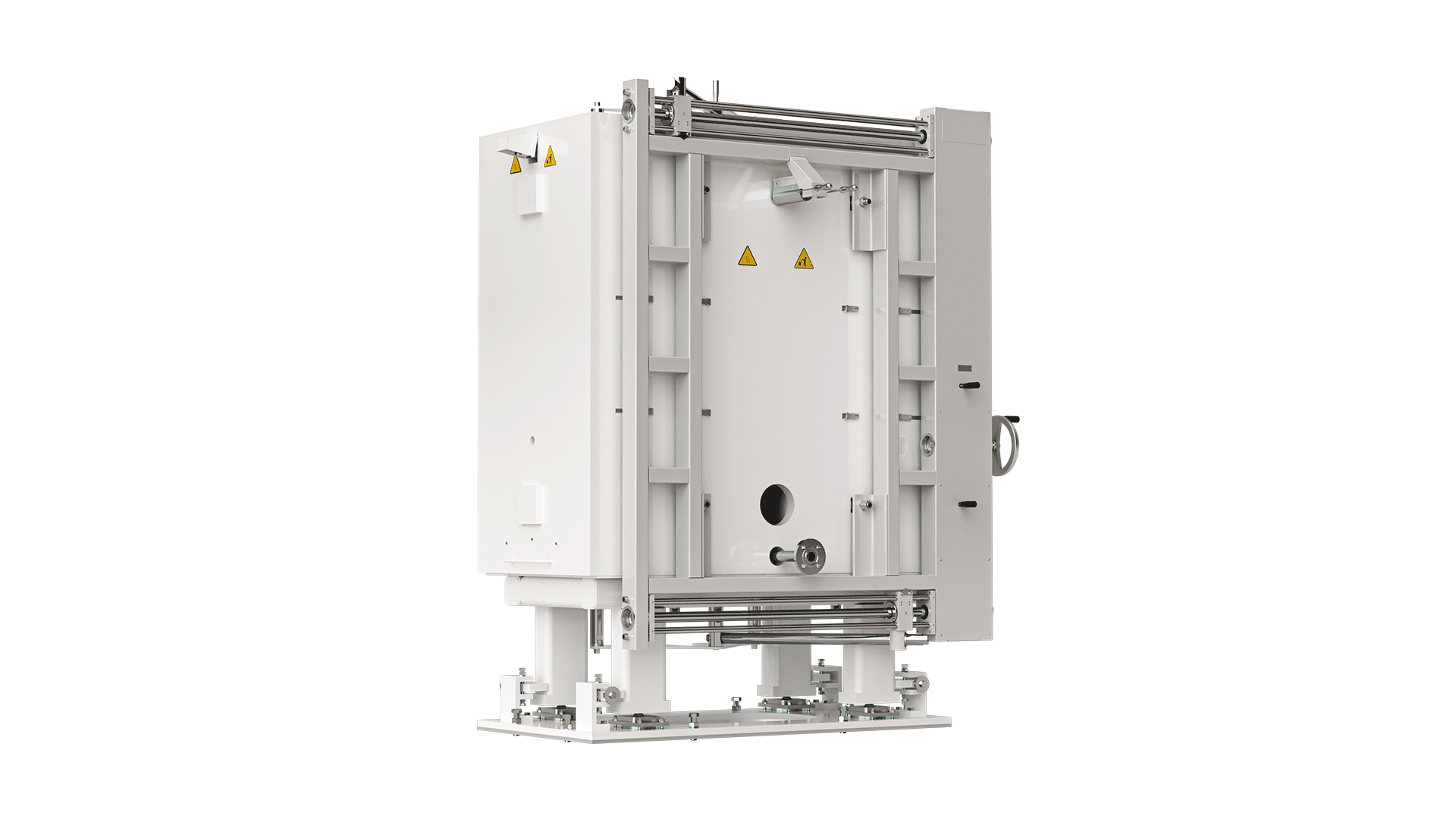

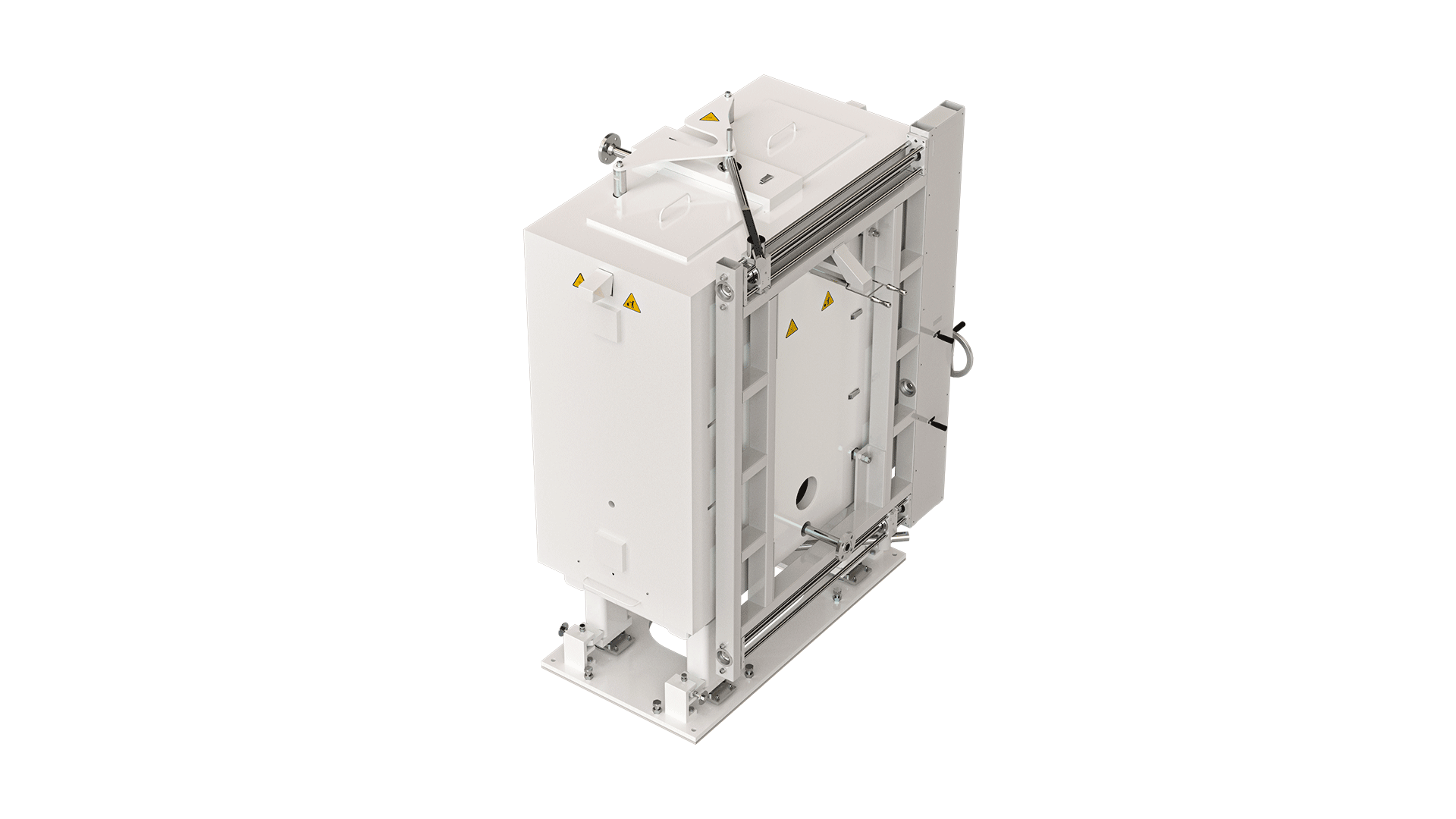

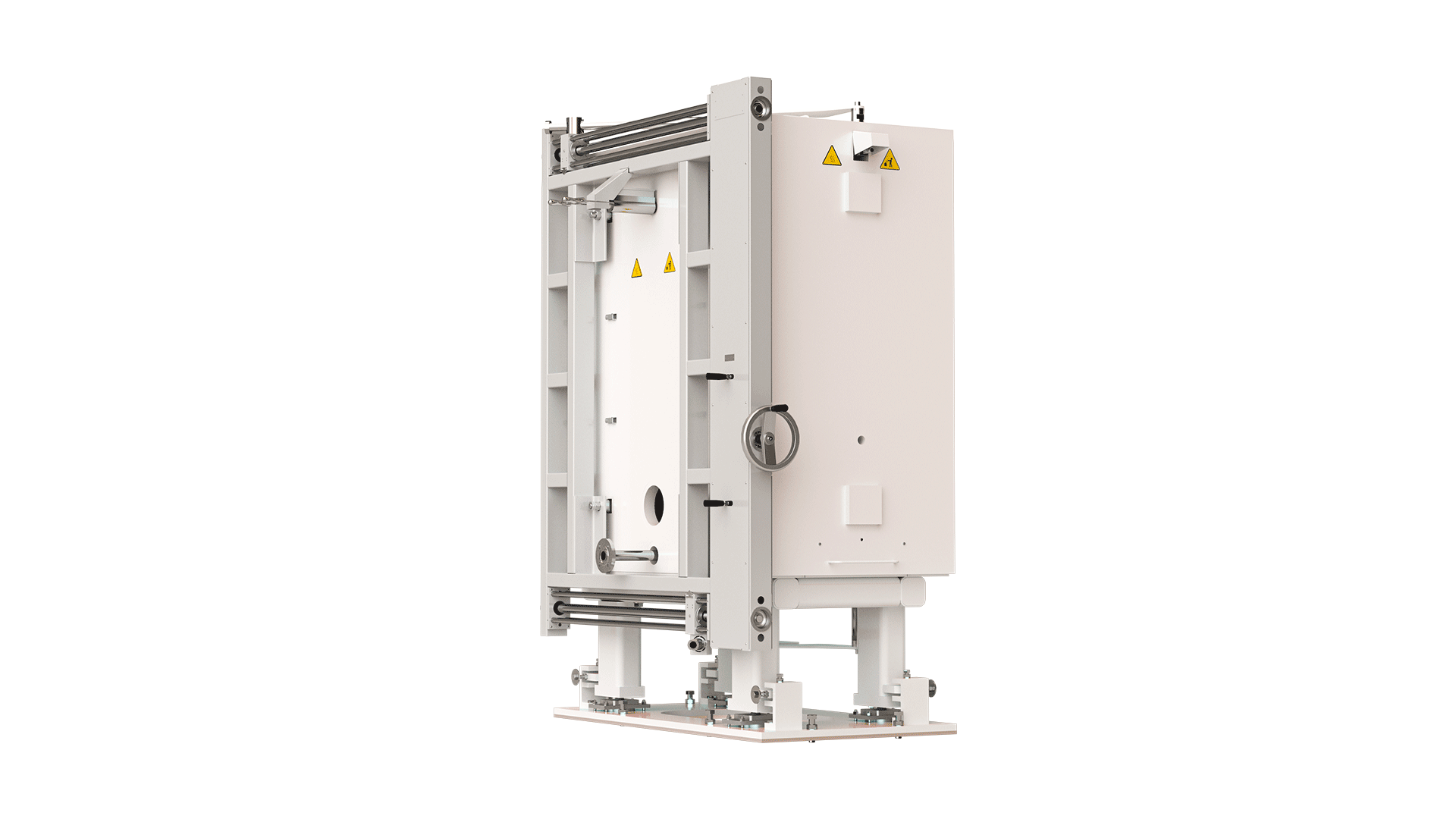

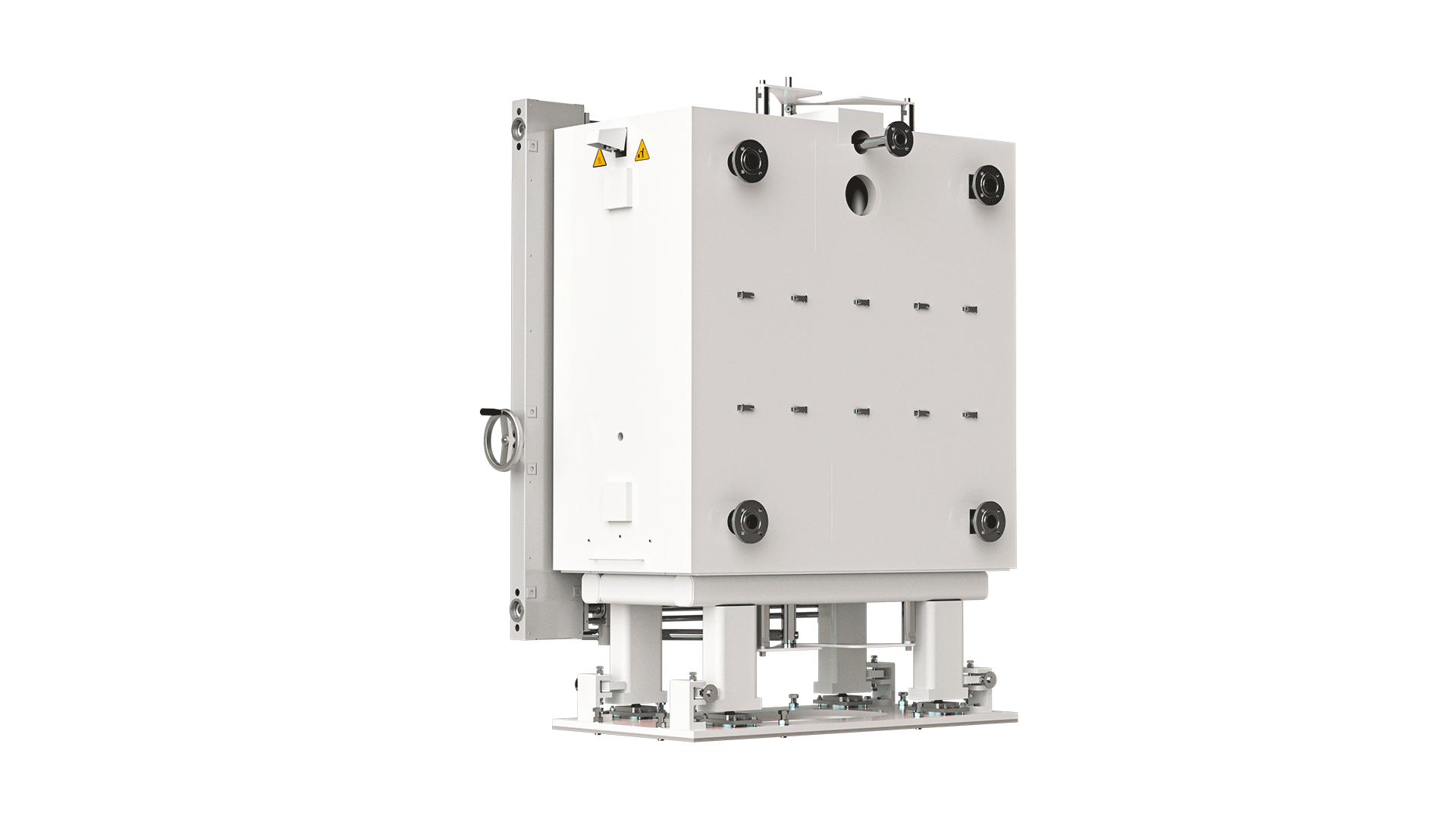

Continuous large area filter with filter areas from 2x 1.8 m² up to 2x 40 m².

Our Non-Stop Filter is a continuous polymer melt filter with two chambers. This means that the filter can be changed without stopping production - trouble-free and efficiently.