From waste to value

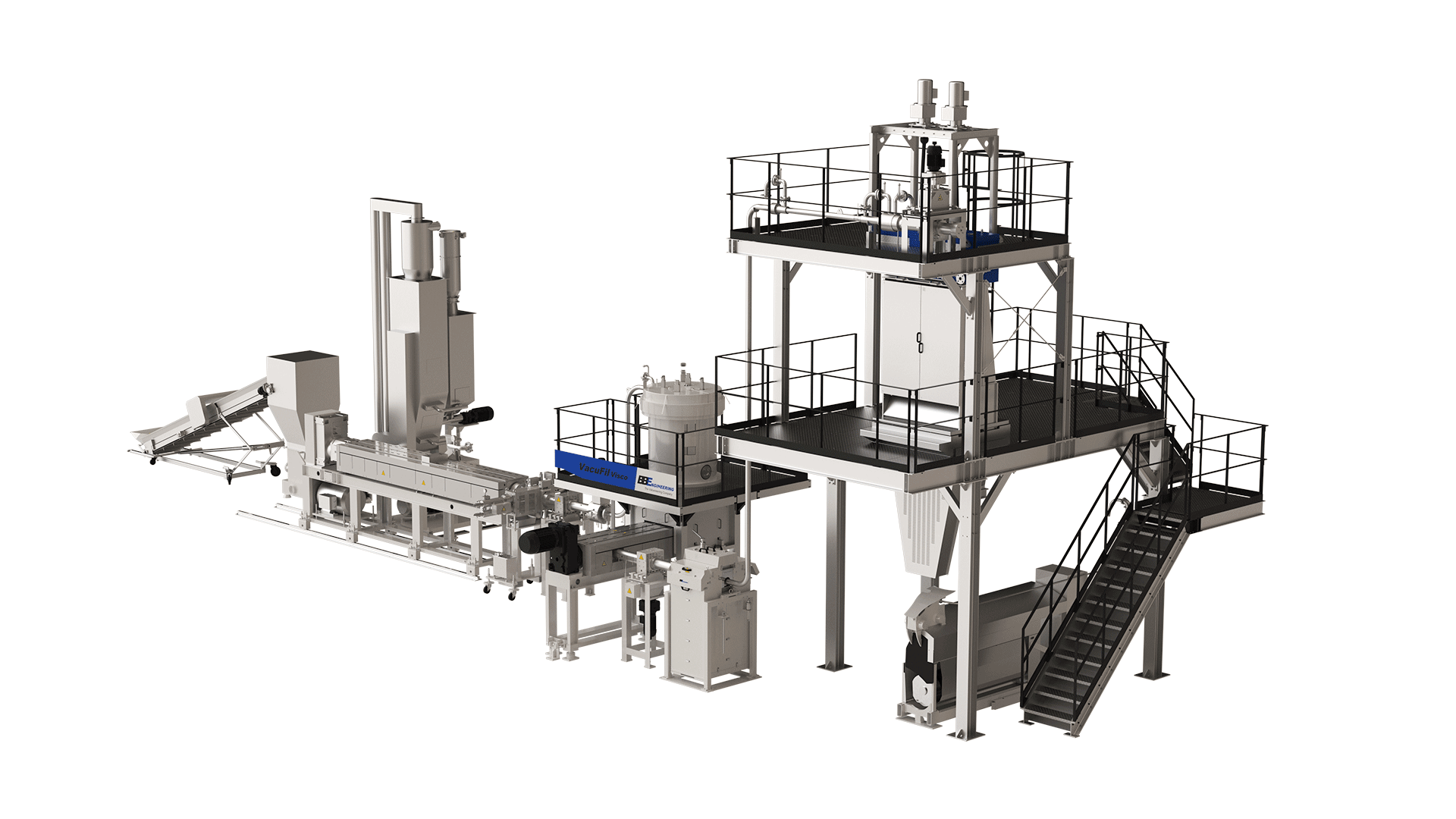

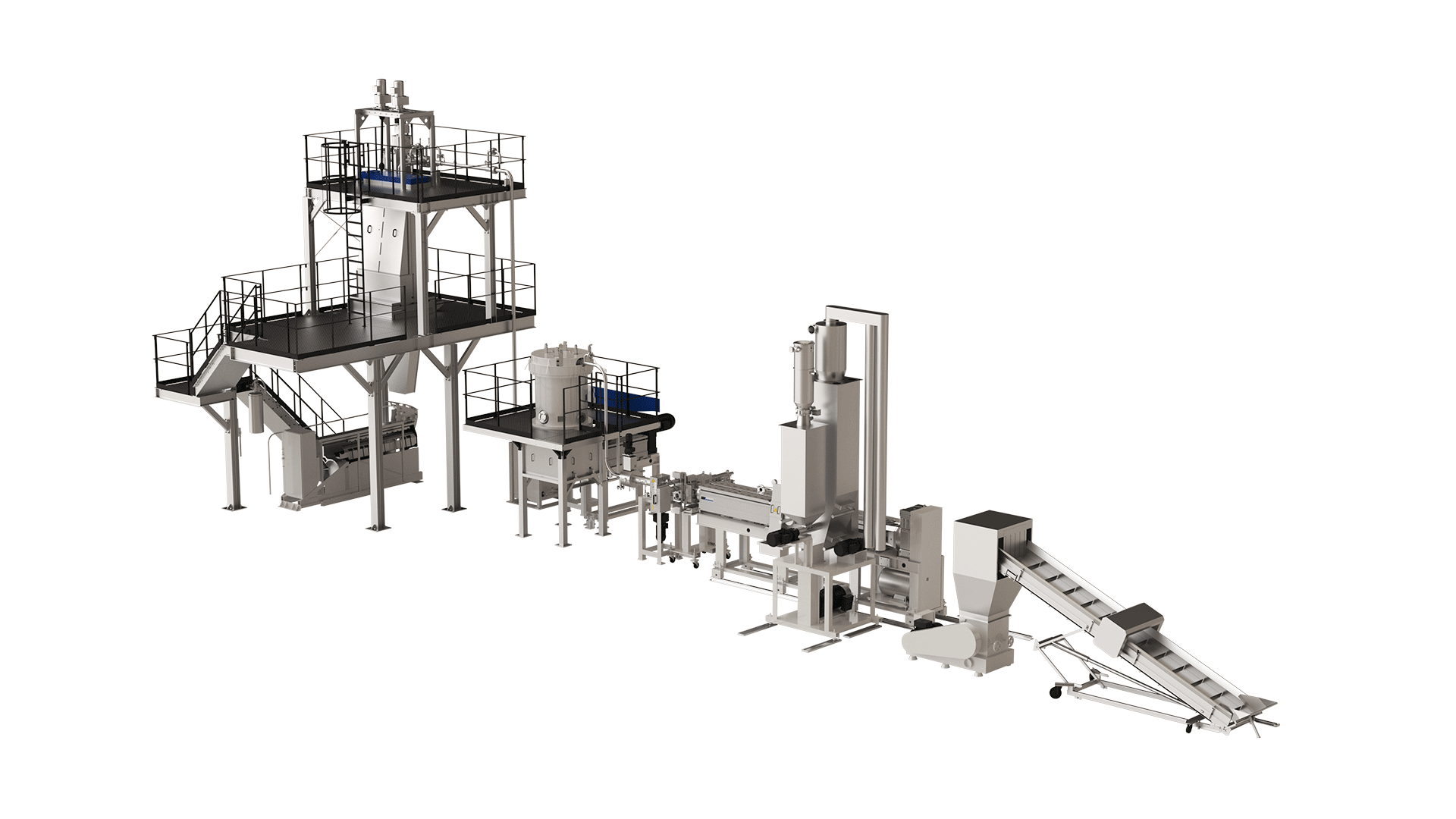

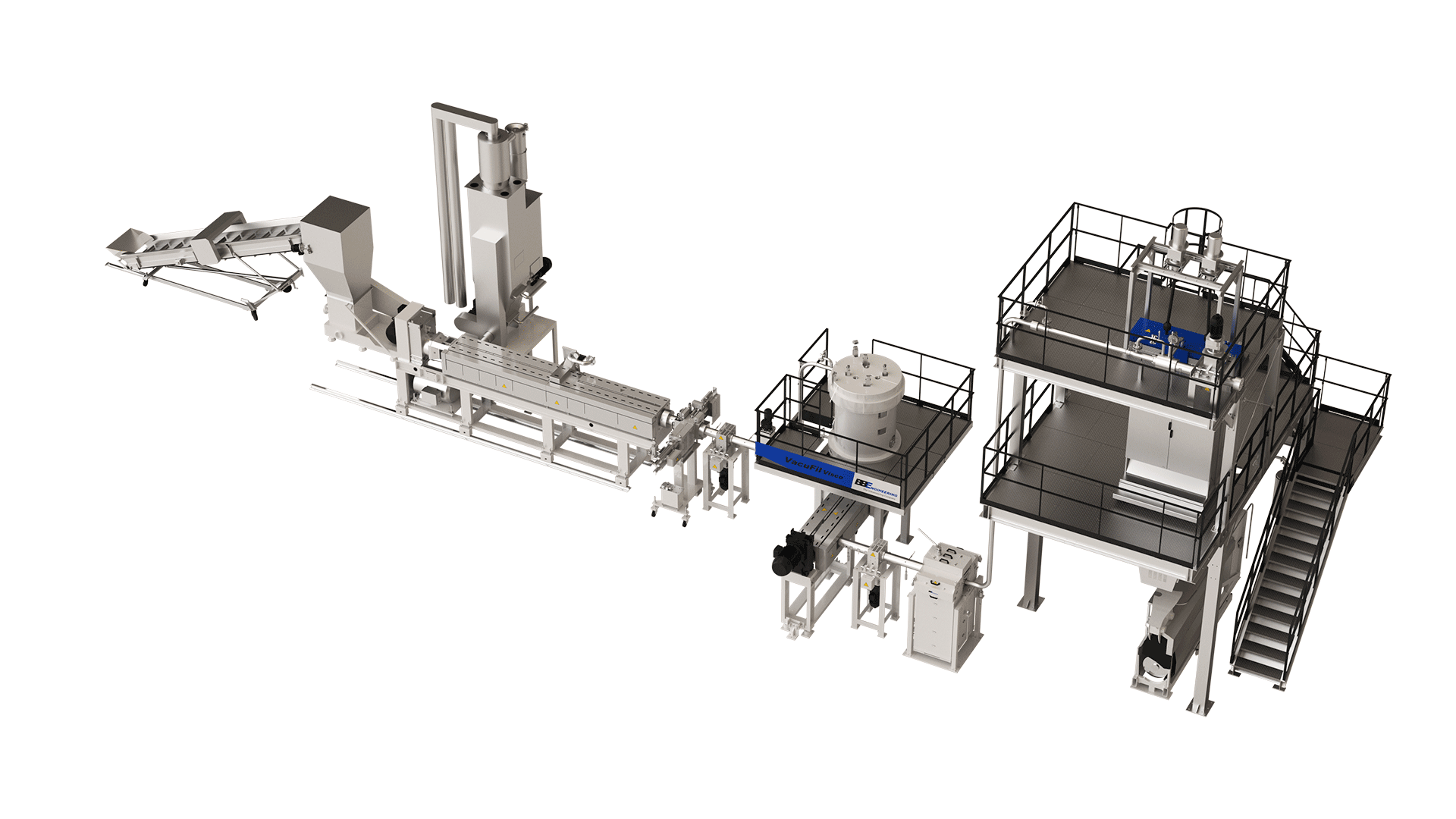

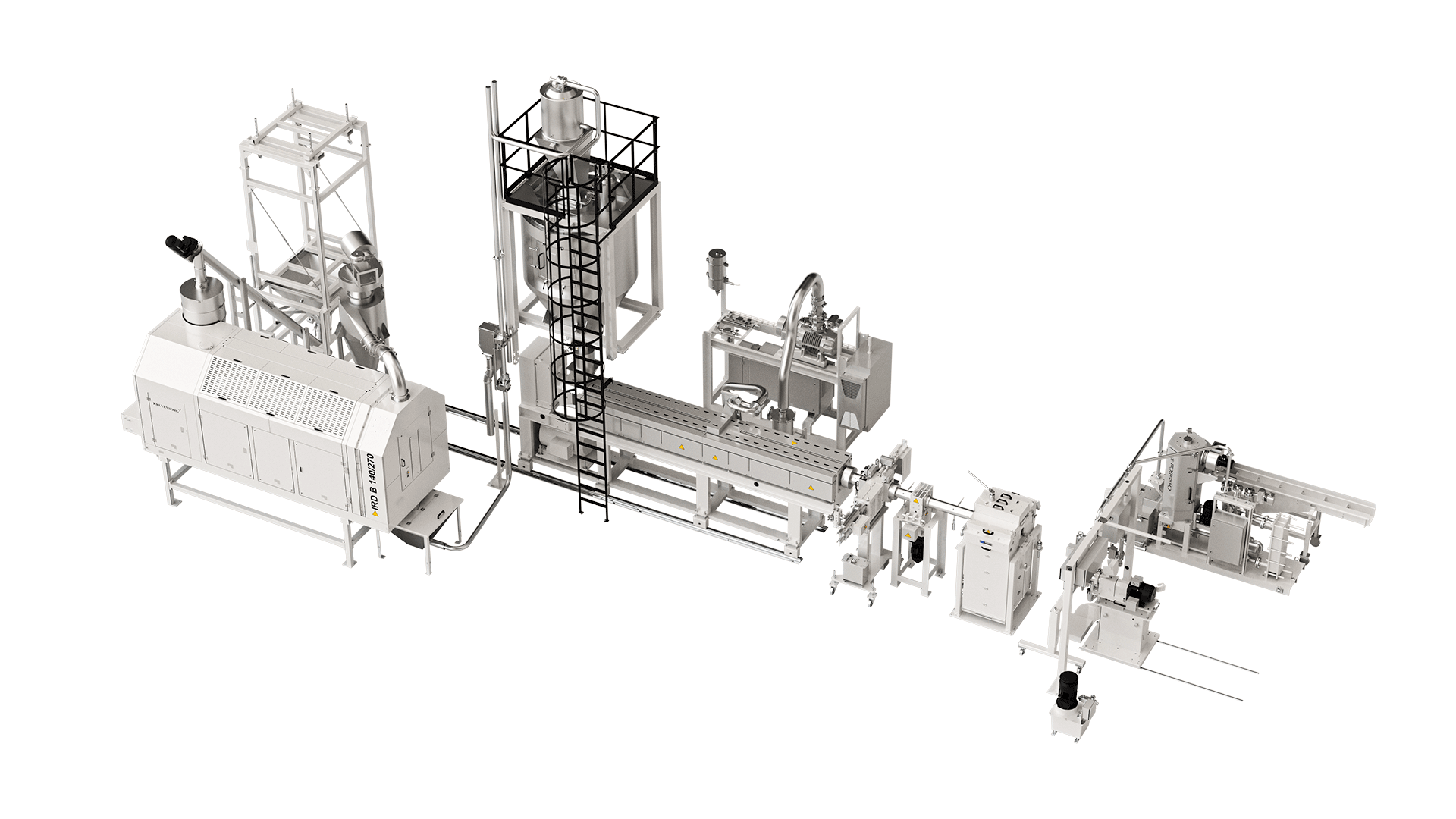

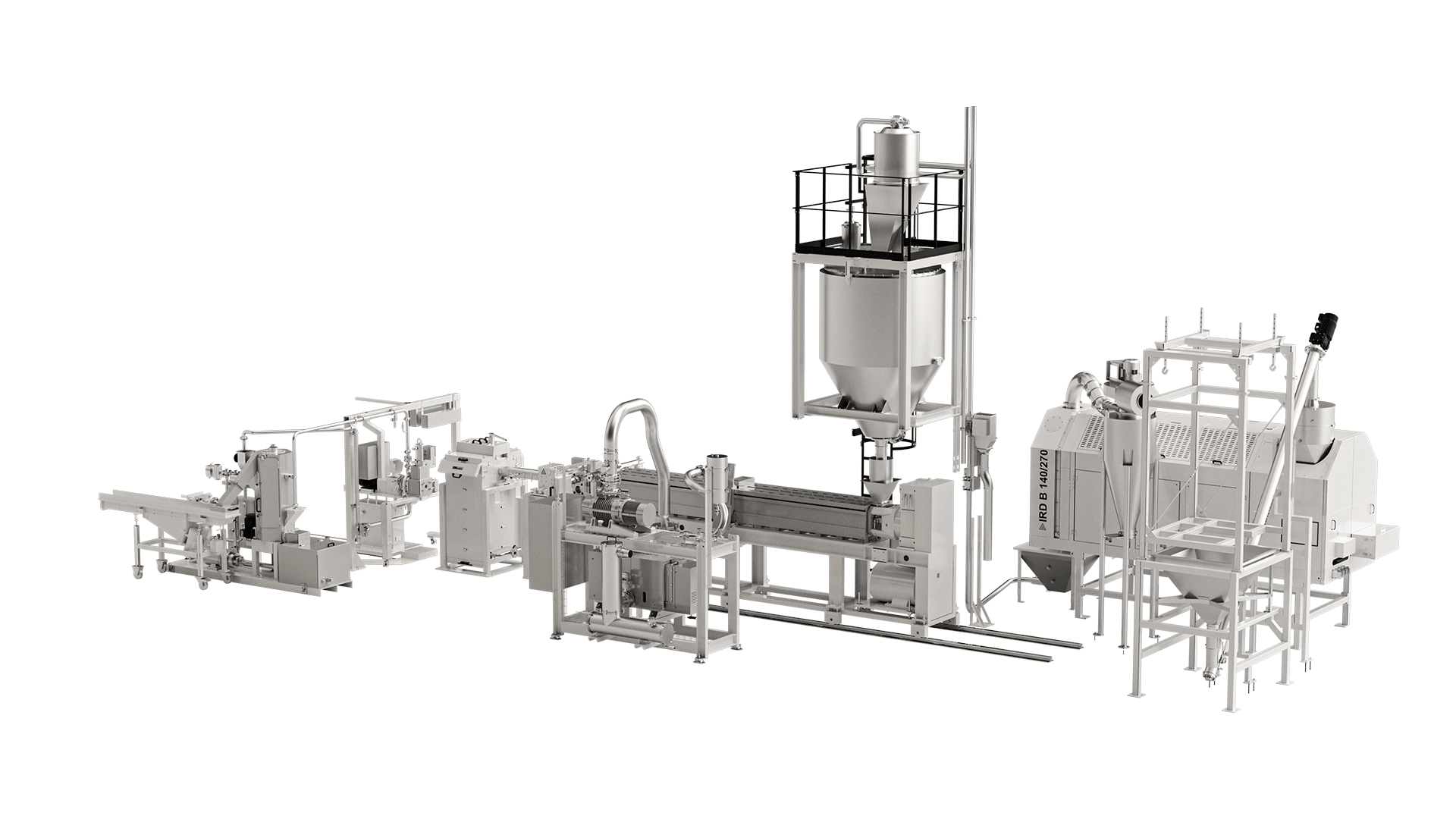

VacuFil® is a unique and innovative PET recycling line, uniting gentle large-scale filtration and targeted IV regulation for consistently outstanding rPET melt quality. It processes a variety of input materials - post-production and post-consumer. The patented key component Visco+ vacuum filter quickly and reliably removes volatile contamination.