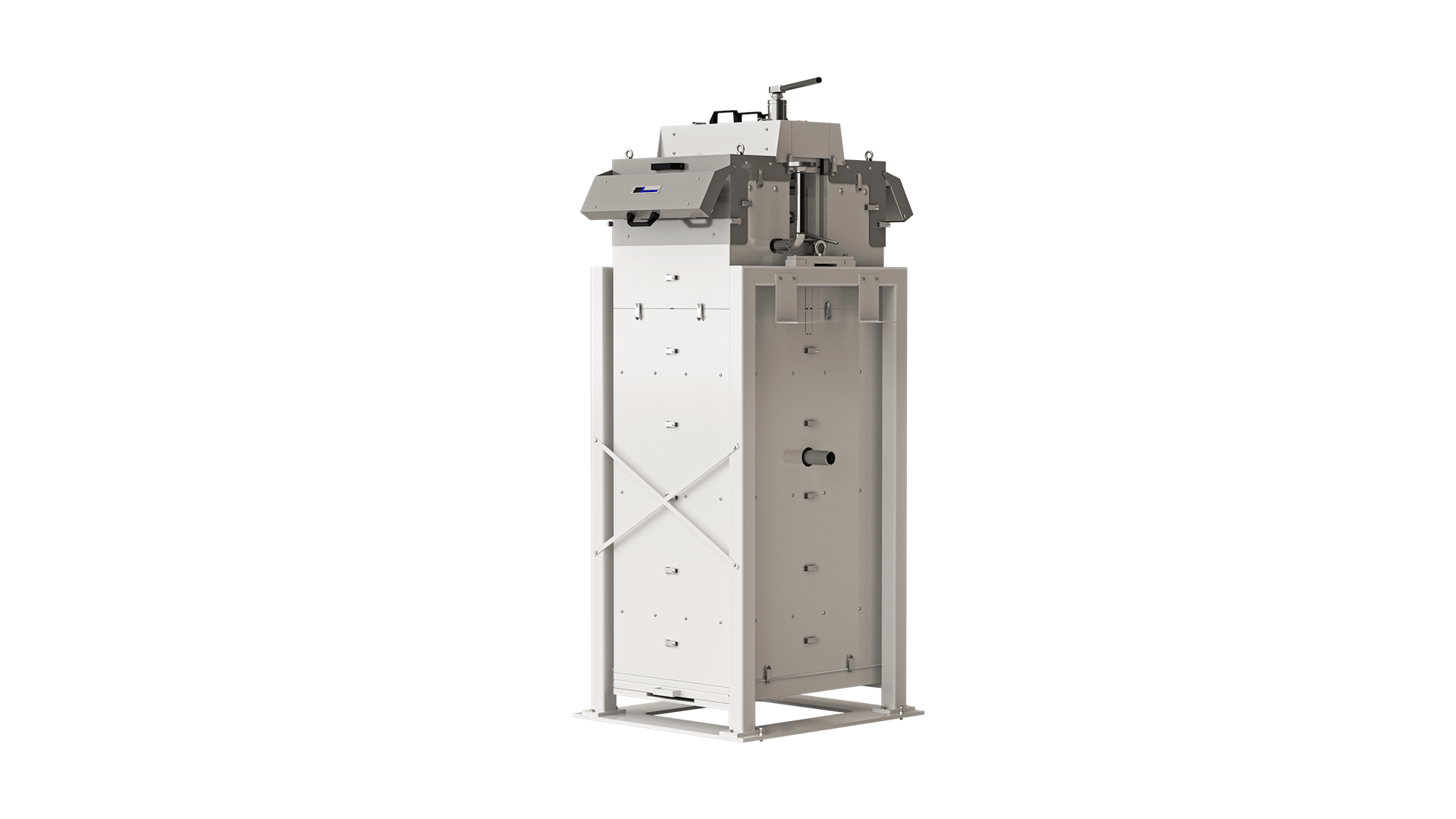

Continuous polymer filter with filter areas from 2 x 0.4 m² to 2 x 8 m²

The Continuous Vertical Filter is a continuous polymer melt filter with two chambers. Its design is specifically for (but not limited to) spinning equipment.

The Continuous Vertical Filter is a continuous polymer melt filter with two chambers. Its design is specifically for (but not limited to) spinning equipment.

(other PET processes on request)