For the highest demands on melt quality and throughput

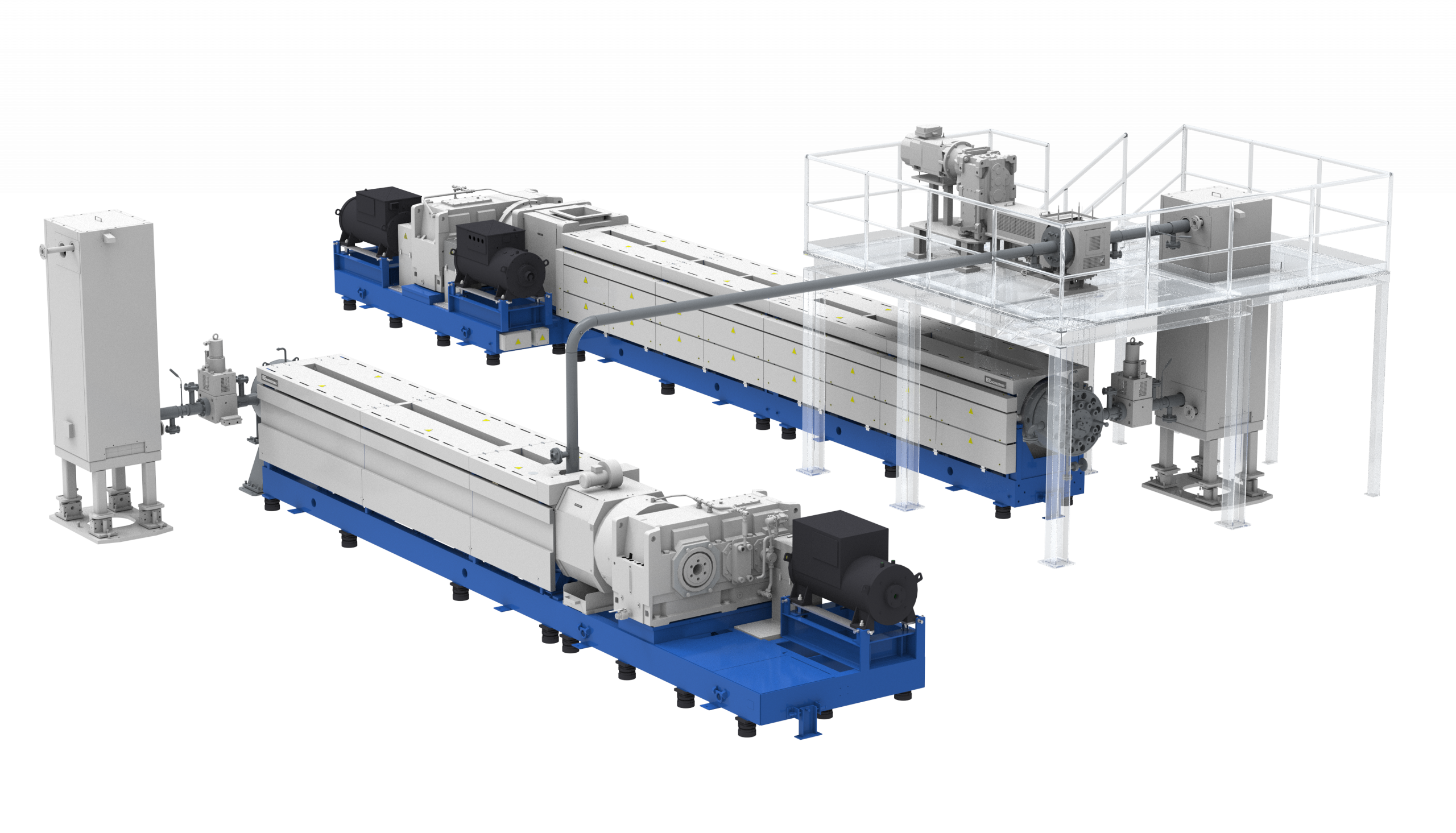

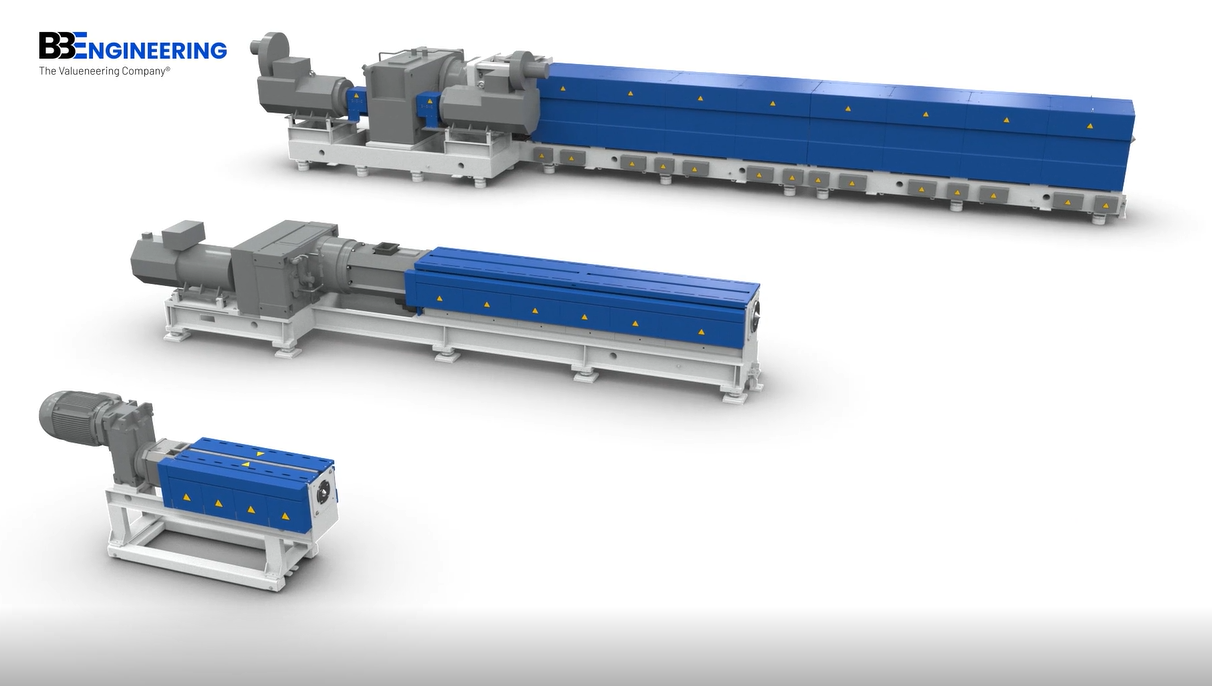

Cascade extrusion is the solution for high output rates while meeting high quality requirements. By connecting two extruders in series, the melting and homogenization process steps can be optimized separately and specifically—for maximum process control, flexibility, and melt quality.

Typical areas of application are film production lines and recycling processes.